Designed in LibreCAD.

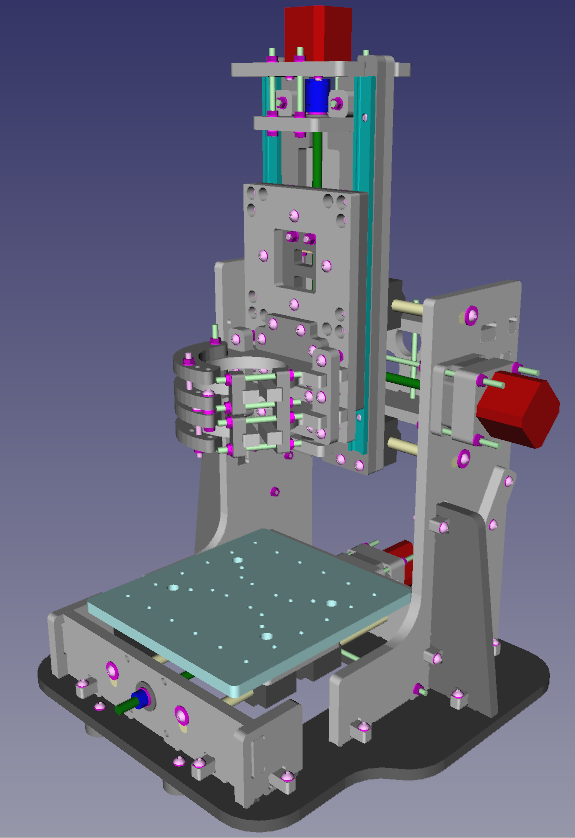

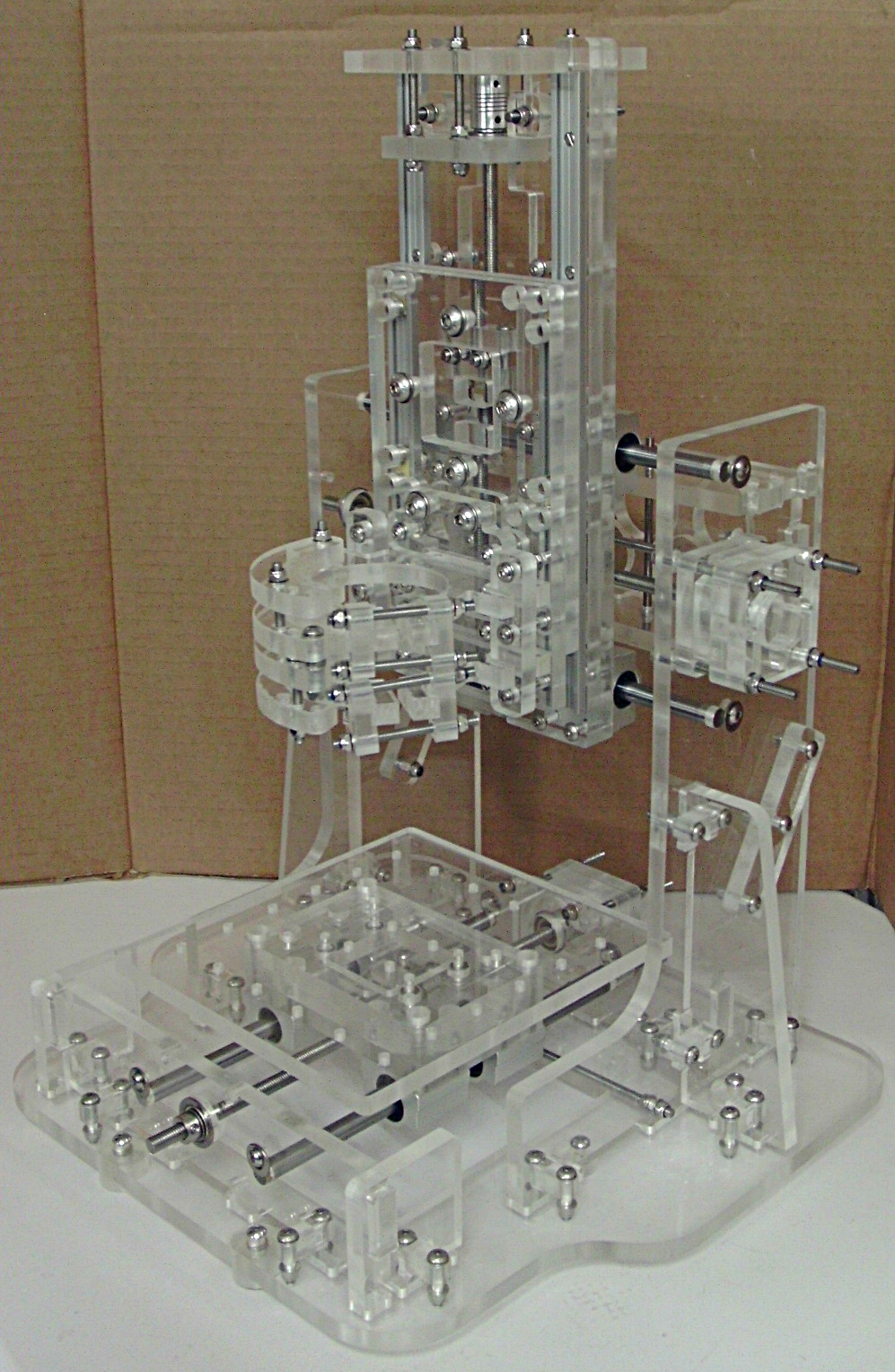

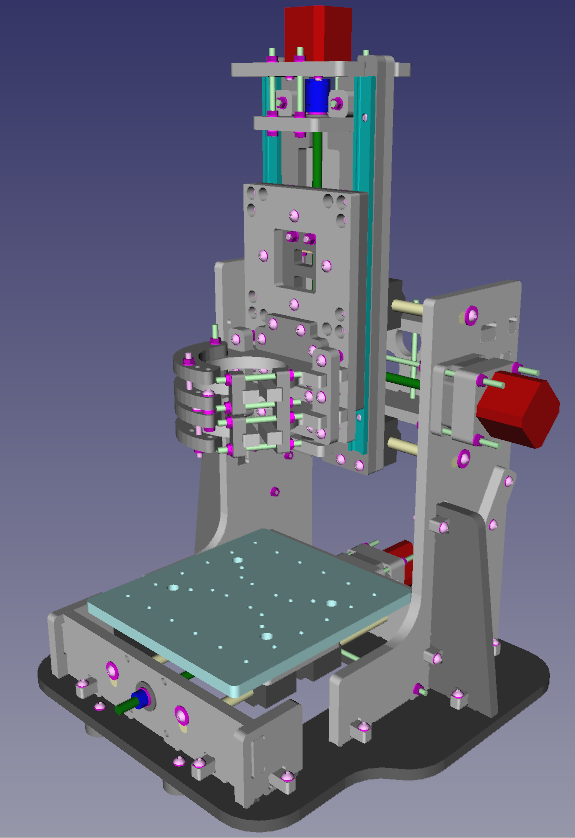

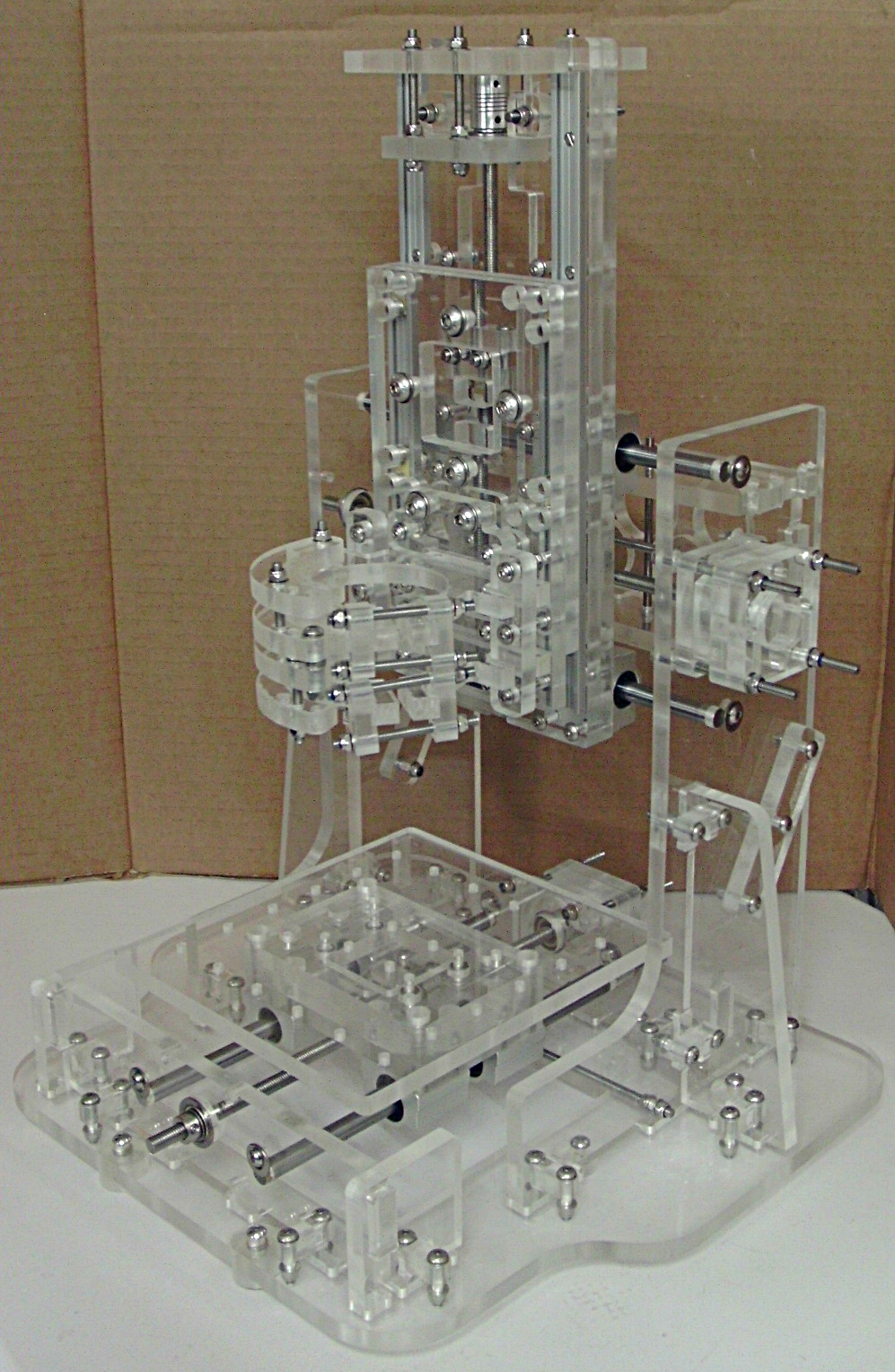

3D Modeled in FreeCAD.

CAM performed by Fusion 360.

Routed by GRBL.

Hand-finished by human.

Spindle mount sized to fit a

DeWalt D26200 router.

| Bologrew

Design |

Do you want to build your own CNC Desktop Milling Machine?

Introducing the Bologrew Design flat pack Milling Machine kit made from 10 mm clear Acrylic.

|

|

Designed in LibreCAD. 3D Modeled in FreeCAD. CAM performed by Fusion 360. Routed by GRBL. Hand-finished by human. Spindle mount sized to fit a DeWalt D26200 router. |

Specifications:

Overall fixed width (excluding stepper motor): 390 mm

Overall fixed depth (excluding stepper motor): 340 mm

Overall fixed height (excluding stepper motor): ~530 mm

Machining envelope width: ~105 mm

Machining envelope depth: ~135 mm

Machining envelope height: ~105 mm

Z axis travel: ~150 mm

Spindle mount diameter: 68.75 mm (to fit DeWalt D26200 router)

Weight (excluding stepper motors and router): ~8.8 kg

Weight (including minimum NEMA 17 stepper motors and router): ~13.86 kg

Kit comprises 4 sheets of routed Acrylic 570 mm by 370 mm x 10 mm plus machine screws, washers and nuts.

The full parts list, required tools and step by step instructions can be found in the Build Manual.

Price £TBA

Do you have a GRBL-based CNC controller and want to upgrade to a Huanyang VFD with an air or water-cooled spindle?

This GRBL-RS485 module connects to your GRBL drive and direction pins as well as the external Hold/Resume/Abort pins and converts the PWM drive signal into the appropriate VFD commands and sends them to the VFD over RS485. Once the module has been configured using a computer with an RS485 interface, it operates in a standalone fashion although it can be monitored by a slave RS485 interface on the bus. Two RS485 connectors are provided to make daisy-chaining easy.

The module can operate in an open loop mode where it just sends the desired speed to the VFD or it can operate in a closed loop mode where it triggers the GRBL hold line when it detects a speed change, sends the desired speed to the VFD and then waits until the actual VFD speed is within 5% before triggering the GRBL resume line to continue. The module can also do a controlled speed ramp down before turning off the spindle if it detects a spindle stop from the GRBL drive signal. This can make the spindle stop more quickly in a controlled fashion but it is not recommended for use with air-cooled spindles. The module has a pump output pin which is high whenever the spindle should be turning. This can be used to control the pump of a water-cooled spindle.

Additionally there are two digital input or 10 bit ADC pins and two digital output pins which can be controlled by another RS485 interface on the bus.

The configuration and operation manual is available here.

The configuration and monitoring software is available here.

Price £20

Have you tried connecting your GRBL-RS485 module or other RS485 interface to your VFD controller and found it doesn't work properly or even that connected devices crash? The problem is that VFDs generate enormous amounts of electromagnetic interference. You can put them in metal boxes, fit power inlet filters, use proper shielded cable for the spindle output and even fit ferrite cores to cables to contain the noise but connecting an RS485 communication lead can provide an easy route for noise to leave the system and be directed straight into the electronics in your control box.

The solution is to fit an RS485 isolator into the communication cable.

This module can be fitted into the communication cable close to the "noisy" VFD end. Ideally the noisy end should be powered by a 9V battery (NiMH is fine, +6V to +14V is the acceptable range - the current draw is typically less than 40 mA) as this provides a clean stable supply. Theoretically the "noisy" end could be powered directly from the VFD if it has something like a 10V output but I strongly recommend against it unless you also fit an additional voltage regulator and protection circuitry (my VFD destroyed a prototype when connected in this fashion!). The "quiet" end can be powered directly from your control box (+8V to +13V so a +12V line is ideal). If you are using something like Cat5 cable for your communication lead then you have plenty of free cores to use for the power and ground. The noisy and quiet sides of the module are electrically isolated so the two grounds must not be connected to each other. The module is protocol independent, will operate up to at least 38400 bps and provides bus termination for both sides of the module as it is also a bus repeater. Since RS485 is half-duplex, the module starts in receive mode on both ends and switches one end to transmit once the other end starts to receive data. The module switches back to both ends being in receive mode once the time delay after the end of data transmission expires. The default time delay is 8 ms but by shorting the "Mode" jumper, powering up the module and using a terminal program at 9600 bps connected to the quiet end, you can alter the time delay from 2 ms to 32 ms in 2 ms increments which is then stored in flash memory for subsequent use.

The configuration and operation manual is available here.

Price £25

For more information about any of these products, contact us by email at "design@bologrew.net".